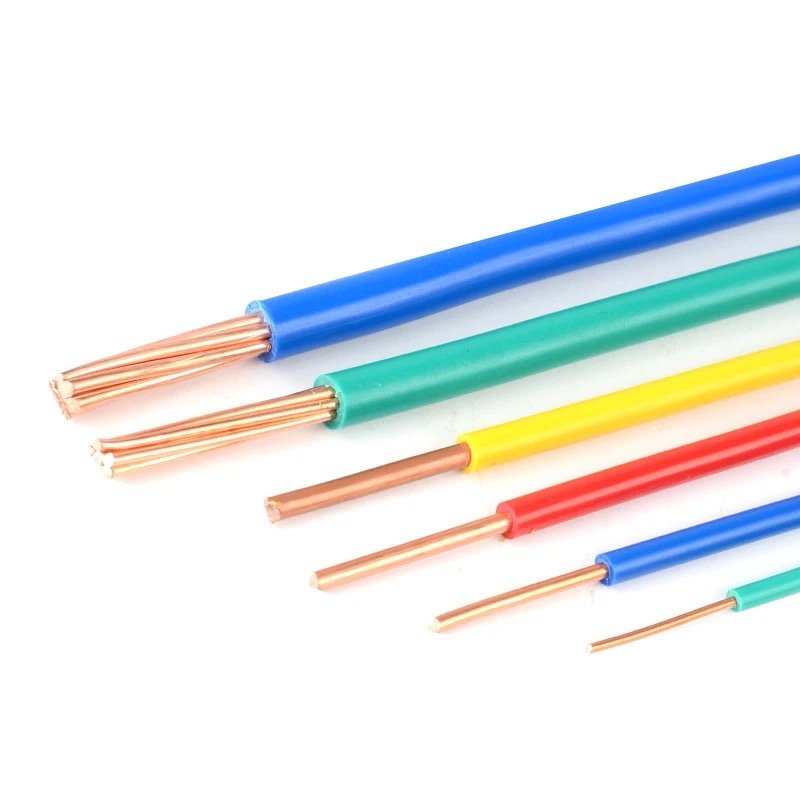

Although the wire and cable is small and heavy responsibility, whether the quality is passed, is directly related to the safety of the circuit. Many fires, electric shock accidents are caused by poor quality of wire and cable, so how to identify the quality of wire and cable?

- Look at Appearance

If the product is qualified and of good quality, the following contents shall be marked on the outer package: quality system certificate, certificate of qualification, factory name, factory address, inspection seal, production date, trademark, specification, etc.

- Look at Conductor Material

Check the conductor material of the wire. General wire and cable with copper core. But the purity of copper is different, and its conductivity is also good and bad. The best is generally purple red, a little red, less impurities, soft texture. If the conductor is white and light in color, it proves that the impurities in the copper are more; If the conductor is black and the sense of hierarchy is strong, this copper is commonly known as “iron copper”, and there is a great hidden danger in use.

- Look at the Position of the Core

Look at the position of the core conductor, a good cable conductor must be located in the center of the insulation layer. Not in the center is due to not meet the process requirements, caused by the phenomenon of partial core, in the use of low-power electrical appliances can meet the performance requirements, once the use of high power, will cause the current heating up the thin side is likely to be broken down by the current.

- Text Weight

Good quality wires are generally within the prescribed weight range. For example, the commonly used plastic insulated single-strand copper core wire with a cross-sectional area of 1.5 has a weight of 1.8 ~ 1.9 kg per 100 m. Poor quality wires have insufficient weight, either insufficient length, or excessive copper core impurities in the wire.

- Text Fold

Take a wire repeatedly bend by hand, fold in half several times, those who feel soft, good fatigue strength, plastic or rubber feel elastic and no crack on the insulator of the wire is superior. If the insulating layer is white, cracked or the conductor is broken, it proves that there is a problem with the quality of the wire.

- Text Antiflaming

Take a lighter to light the wire, qualified wire, a blue smoke, after the insulation layer lit the lighter away, should be extinguished within five seconds. Otherwise, it is the wire that does not meet the fire standard. This kind of wire is easy to cause accidents such as leakage and fire.