About Us

Goldensea Cable was established in 2004 , we have been manufacturing Internet cable, Power cable,Solar cable and Some of special cables for more than 20 years.

We keep putting investments in evolving our technology and plant management. We are certified by ISO9000 Quality System, ETL, CPR etc..

We have the stringent quality measures in place to ensure our good quality consistency. Company adheres to the approach: first-class management, industry-leading quality and high quality service.

Our advantage

High Efficiency

High Efficiency Delivery Schedule-When we received the customer’s order,the purchase of raw materials and the mold are completed immediately.Delivery completed within one month.

Competitive Price

Cost Effectiveness Solution-Becasue the company has rich purchaing resources and management experience, so the purchase cost and production have been controlled effectively.

Quality Assurance

We have complete testing equipement to ensure the quality of raw materials and finished products.

OEM&ODM

We offer OEM & ODM services provides , allowing clients to customize products with brand identity. Meeting diverse market needs and specification.

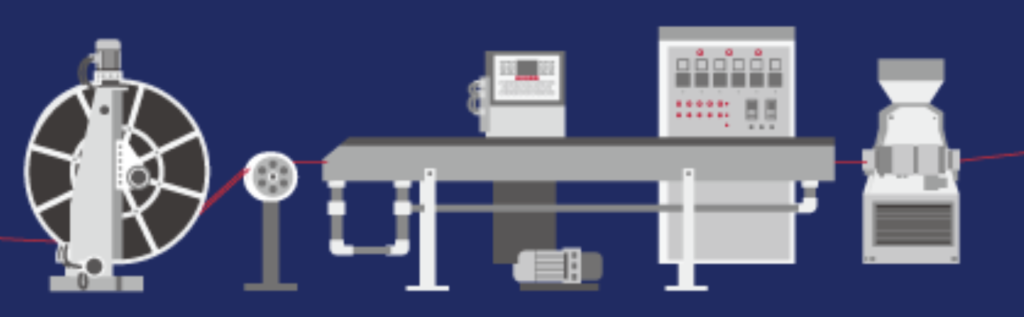

Factory Equipment & Instruments

1400 Cable Laying Machine

Cable Drawing Machine

High Speed Packing Machine

Continuous Tube Annealing Machine

Interlocking Armor Machine

High Speed Small Drawing Machine

Professional production process and specification

1.Wire drawing process

The advanced single-time continuous-pull wire drawing technology is adopted to ensure that the performance of the single-wire of the conductor is stable and the resistivity is qualified, and the ductility and the electrical conductivity of the single wire can be improved.

3.Insulation procedure

PVC power cables and cross-linked cables use different processes, but the two processes are equally exquisite. Using the international DC drive electrical system and automatic material drying equipment, the main machine is controlled automatically to make the appearance of cable .

The whole process of the cable is closed and specialized management. Each process is subject to the design and specification of the engineer's scientific rigor. It is equipped with professional technicians to check and make sure that the production quality of each cable is not in any difference with our standard.

2.Stranded Operation

The production links are ring-ring, closely related, and the twisted-wire process adopts the advanced 54-plate-fork winch, the 37-disk-frame hinge and the 7-coil-twisted pair to be different and twisted, and the equipment and the technical advantages are fully utilized, the outer diameter is uniform.

4. Wire drawing process

Make full use of the equipment’s performance, prevent damage and distortion and deformation in the production process, and provide the advanced steel strip rolling machine for the armored cable, so that the section pitch of the armored layer of the cable is uniform, the coating is tight and firm, and the appearance is more structured

Test Equipment